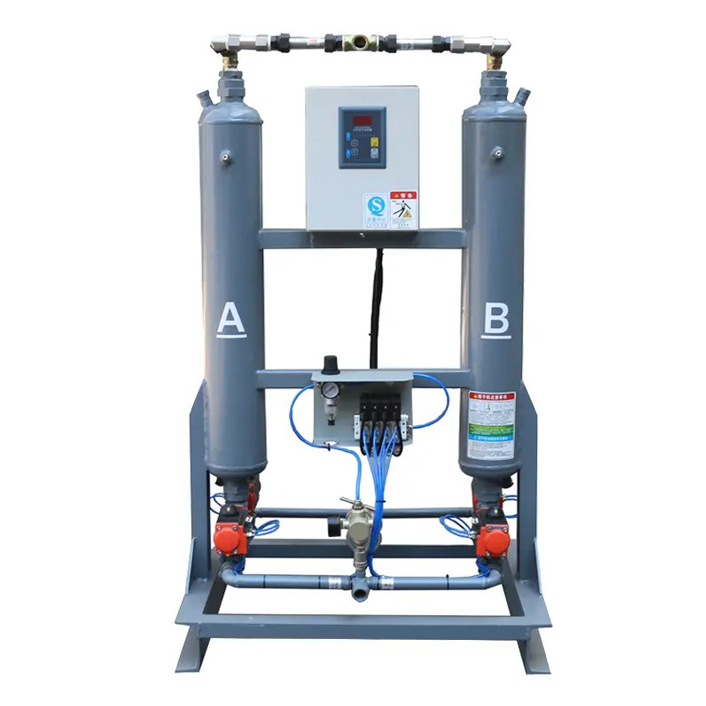

Desiccant Air Dryer

DH Series Combined Industrial Compressed Air Dryer

- Product ID:Desiccant Air Dryer

- QQ:89080830

- Phone: +86-18080420046

- Tel: +86-28-84369018

- Email: topefg@hotmail.com

- Time: 2021-11-15 13:04:01

Combined dryer is a new energy-saving air-treatment equipment. It mainly includes three parts. That is,refrigerated dryer, precision filters andcompressed air dryer desiccant.

It takes fully the advantages of refrigerant dryer anddesiccant air dryer for compressor. Therefore, we can get a lower dew point. Moreover, the energy consumption is very low. So this combinationcompressed air dryer systemhas excellent performance.

1. Technical specifications of combination compressed air dryer desiccant

| SuitableMedium | Compressedair/nitrogen |

| CoolingModeofRefrigerantDryer | Air-cooled |

|

RegenerationTypeofDesiccant AirDryerforCompressor |

Heatlessregenerationµ-heatedregeneration |

| AverageConsumptionofRegenerationAir | 4~6%forheatlessdryer,3~5%formicro-heateddesiccantdryer |

| InletAirPressure | Std.7bar|Min5barMax:10bar(highpressurecustomizable) |

| AirInletTemperature | Std.50℃|Max:80℃ |

| AmbientTemperature | Std.32℃|Min2℃Max:45℃ |

| PressureLoss | ≤0.61bar |

| AvailablePressureDewPoint | (-20℃,-40℃,-70℃) |

| OutletAirOilContent | ≤0.01PPM |

| DesiccantBeads | Highefficiencyactivatedalumina+molecularsieve(3~5mm) |

| CompressedAirFilter | Pre-filter,dust-removalfilter,oil-removalfilter,activatedcarbonfilter |

| WorkingPrinciple |

Pre-cooling+lowtemperaturecondensation+efficientwater separation+heatrecovery+precisionoil-removal+deepadsorption |

2. Advantages of Combination Compressed Air Dryer System

① Energy saving

There is no air loss for refrigerated dryer. However, the air consumption of heatless dryer is generally 13%. And micro-heated dryer also has about 6% air loss.

But combination dryer has lower air consumption. For example, heatless combination type is 4~6%. And micro-heated combination type is 3~5%. So it is more energy efficient.

② More stable and lower dew point

Combination dryer is ideal for obtaining low dew points. Air compressor produces high-temperature, high-humidity compressed air. Firstly, refrigerant dryer cools them to about 2~10°C.

At this time, it has discharge most gaseous water. What’s left is compressed air with very low moisture content. So the working load of compressed air dryer desiccant is very low. Thus we can achieve -70℃ dew point easily. Also, the dew point is more stable.

③ Reduce the floor space

Refrigeration dryer and desiccant air dryer for compressor are on the same base. So it reduces the floor space.

④ Easy to install

Filters and piping are already installed on compressed air dryer system. Therefore, it reduces installation process of the user.

3. Why choose our combination refrigerant & desiccant air dryer for compressor

① Our combined dryers serve customers together with famous air compressor brands. For example, our 6.5m³/min combination dryer is working with Kobelco oil-free air compressor as above picture.

Moreover, our other compressed air dryer desiccant often work with Atlas Copco, Ingersoll Rand, Sullair, Kaeser, Hitachi, etc.

② Refrigerated dryer uses famous brand refrigerant compressors. For instance, we use Hanbell, Danfoss, Copeland and Panasonic brands. Therefore, the cooling capacity is super strong.

Besides, there is built-in safety protection. So it has stable performance and high efficiency.

③ Refrigerant dryer is with precooler and heat exchanger. Therefore, it can reduce the load of refrigerant compressor. So compressed air dryer system can adapt to severe working conditions. The maximum inlet temperature can withstand 80 ℃.

④ Our desiccant air dryer for compressor adopts high-performance adsorbent. And the pneumatic control valve is also imported brand. So it has reliable performance and long lifetime.

Moreover, there is an airflow diffuser at the bottom of adsorption dryer. Therefore, it ensures the long-time contact between compressed air and desiccant beads. Then dew point can be guaranteed.

⑤ In addition, we use high-quality filters. The filter element adopts USA HV filter paper. The housing is cast aluminum. The maximum pressure can reach 16bar. The temperature of the filter is 80°C.

The lifetime of filter element is generally 8000 hours. Shell life can be up to 10 years.

4. Working principle

It is a combination of refrigeration dryer + compressed air dryer desiccant. Preliminary drying in a refrigerated dryer. It removes a lot of moisture. Thereby, the workload of the adsorption dryer is greatly reduced.

In addition, only a small amount of water remains. They are dried by regenerative desiccant air dryer. As a result, we get low dew point dry air.

The adsorption dryer has a lighter workload. Therefore, the required regeneration air will be greatly reduced. It makes compressed air dryer system more energy efficient.

Specific process flow of combination air dryer:

Firstly, the compressed air enters the precooler. They exchange heat with dry compressed air from desiccant dryer. So it will increase their temperature. At the same time, the temperature of the compressed air entering the evaporator is reduced. Fianlly, it removes some water. Also cool them down to room temperature. The workload of the evaporator is also reduced.

Then enter the evaporator for heat exchange. Cool the compressed air. So it achieve the dew point temperature of around 5°C. At this time, it has completed preliminary dehumidification. Then they enter the desiccant air dryer for compressor.

The adsorption dryer adopts the PSA principle. It can get a lower dew point. Dry air comes out of the adsorption tower. Then they return to the precooler in refrigerant dryer. They will cool hot and humid air. Besides, also will raise their own temperature. So it is also beneficial to the regeneration air.

5. How to choose the combinated compressed air dryer system? (1) Confirm basic paramters

Firstly inform the air capacity, inlet temperature and pressure. So we know which model to choose.

In particular, different inlet air pressures, different the price is also different. The freeze dryer can be 16 bar, 25 bar, 40 bar, 60 bar to 100 bar. And compressed air dryer desiccant can also be 1.6MPa, 2.5MPa, 4.0MPa to 10.0MPa.

Therefore, our combination dryer can also do medium pressure and high pressure.

In addition, also need to tell the dew point. In fact, one of the advantages of combination dryer is the low dew point. We can do it up to -70°C.

(2) Air-cooled or water-cooled refrigerant dryer

Air-cooled refrigerated dryer is easily affected by ambient temperature. Especially in summer, the dryer is under heavy load. So it has impact on dew point. Generally, it requires good ventilation.

There is no such problem for water-cooled dryer. However, there needs the cooling water system. For example, it requires cooling pumps or tower. So the initial investment is relatively large. But the working condition is more stable. If water resources are abundant, we can choose it.

(3) Confirm the desiccant air dryer for compressor

There are many types of compressed air dryer desiccant. Just their energy efficiency is different. For example, the regeneration air consumption of heatless combination dryer is 4~6%. The air losss of micro-heated is 3~5%. So, if energy saving requirements are not high, you can choose them.

However, sometimes customers concern saving energy. At this time, we need to choose zero air loss desiccant air dryer for compressor.

In addition, there is also a modular compressed air dryer system. Its biggest advantage is small size. So easy to transport. For example, the picture below is a 16 bar refrigerant dryer + modular desiccant dryer.

(4) Combination dryer material

Sometimes customers require dryers of stainless steel. For example, the food and pharmaceutical industries require SS304.

We can customize stainless steel refrigerated dryer. And also can produce stainless steel compressed air dryer desiccant. In addition, filters and pipes can also be SS304.

In fact, the housing of our modular adsorption dryer is aluminum alloy. It’s also special for the pharmaceutical and food industries.

6. Combination air dryer user manual (1) Intall the refrigerant & desiccant air dryer for compressor

① The ambient temperature should generally not exceed 40 ℃.

② It needs good ventilation. But don’t install compressed air dryer system outdoors.

③ The installation environment should be dry. There should not be wet.

④ In advance consider the convenience of maintenance. Besides, should maintain a horizontal position. So as not to affect the discharge of condensed water from the dryer.

⑤ We should prevent the dryer from being vibrated by the piping system.

⑥ Pipe diameter should not be smaller than size of compressed air dryer desiccant.

⑦ The pipeline should not be too long. So as not to cause water accumulation and large pressure drop.

(2) Use precautions

① Should intall a power switch separately. Besides, dryer working pressure must not exceed rated value.

② Do not share a protective device. The voltage fluctuation range shall not exceed 10% of the rated voltage.

③ The cables should not be too thin or too long. In order to avoid voltage drop of desiccant air dryer for compressor.

④ The casing of compressed air dryer system should be grounded reliably.

⑤ The power supply voltage is 380V/50HZ. (Other voltages can be customized).

⑥ Also ensure there is good ventilation.

⑦ Check whether the inlet air temperature and pressure are normal.

⑧ We must cut off the compressed air dryer desiccant before maintenance.

⑨ Before maintenance or disassembly, pressure must be relieved firstly.

⑩ Check whether the cooling water is normal.

⑪ After running for 30 minutes, check whether the drainage system is normal.

(3) Compressed air dryer system operation ① Start up

Firstly turn on the start button of refrigerated air dryer. So it starts to work. And wait about 5 minutes. Then let compressed air into dryer system.

Wait for the towers A and B to have the same pressure and stand still. Then turn on the power supply of desiccant air dryer for compressor. Press the “Start button”. So dryer starts to work fully automatically.

② Shut down

Firstly close the air inlet valve of the dryer. Then press the “Stop Button” of the two dryers. So they will stop working. Then cut off the power to compressed air dryer system.

③ Dry the adsorbent

Use self-drying method. Close the dry air outlet valve. Then remove the orifice plate from the regeneration air tube. Increase the amount of regeneration air.

The load of compressed air dryer desiccant is very low now. The bottom layer has very little moisture absorption. A larger amount of finished air is used for regeneration and drying. Its dryness is high.

After 24 hours of drying, wait to reach the required dew point. Then install the orifice plate. Finally, the desiccant air dryer for compressor is in the normal adsorption state.

④ Filling and replacement of adsorbent

We use desiccant beads for a while. Usually three years. If the dew point is too high, it is necessary to check the adsorbent. Remove some from the tower. Check to see if it is contaminated (yellow in color).

If it is, must replace the desiccant pellets. We can take them out from the discharge port. Or fill from the upper loading port.

⑤ Replacement of filter element

The normal service life of the filter element is generally 8000~9000 hours. If the use time is short, the dryer dew point is high. Indicates that the air contains too much oil. So we should replace the filter element in time. At the same time, check whether the oil discharge of the air compressor is normal.

(4) Control panel description of compressed air dryer system

① Refrigerant high pressure meter: show the condensing pressure of the dryer refrigerant.

② Refrigerant low pressure gauge: indicates the evaporating pressure of refrigerant in the dryer evaporator.

③ A tower pressure gauge: indicate the air pressure of tower A of compressed air dryer desiccant.

④ Tower B pressure gauge: show the air pressure of tower B of desiccant air dryer for compressor.

⑤ Start button (blue color): press this button to start compressed air dryer system.

⑥ Stop button (red): press this button to stop the air compressor dryer.

⑦ Power indicator (red): if light on, it shows that the external power supply is normal.

⑧ Running indicator light (green): when this light is on, it means that the dryer is running normally.

⑨ Abnormal indicator light (yellow): when this light is on, it indicates that compressor air dryer is faulty.

(5) Electrical and automatic control

The refrigerant dryer adopts a closed refrigeration cycle. It’s with thermal expansion valve and hot air bypass valve. The refrigerant expands directly. Finally enter the evaporator.

Sometimes, the production conditions and environment will change. This can cause changes in the evaporator heat load. At this time, both these two valves are automatically adjusted. Therefore, it can ensure constant temperature of dryer evaporator. So it prevents ice jams.

In addition, our compressed air dryer system are with safety protection devices. For example, it has refrigerant high and low pressure controller. Also has current overload protector. In case of refrigerant leakage, it will cut off power automatically. Therefore, the compressor will be not damaged.

The compressed air dryer desiccant has a PC program controller. It can control the alternate adsorption and regeneration of twin towers. Besides, it can display the working status in real time.

Moreover, it can control desiccant air dryer for compressor with time delay. Easy to use. And works reliably. The display is intuitive and clear.

(6) Combined dryer maintenance ① Maintenance of sewage system

| PartsName | MaintenanceContent | MaintenancePurpose |

| Manualdrainvalve | Manuallydrainonceaday |

Inordertoavoidfailureoftheelectronic drain.Atthesametime,draintheoiland waterfromthecompressedairdryersystem intime. |

| Ytypeanti-blockingballvalve | Cleantheinnerfilteronceaweek | Inordertopreventblockage |

| Electronictimingautomaticdrain |

Manuallytestthedrainageonceaday; Cleantheinnerfilteronceaweek; |

Drainthewaterfromrefrigerateddryerand compressedairdryerdesiccantintime. |

| Floatautomaticdrainer |

Observethedrainageeveryday; Cleantheinnerfilteronceaweek; |

Sametoabove |

② Filtration system

| PartsName | MaintenanceContent | MaintenancePurpose |

| Oil,dustandwaterremovalfilter |

Mustreplacethefilterelement 1~2timesayear |

Reducepressuredrop.Enhancethefiltering effect.Preventsagingglassfibersfrom clogginglines |

| Regulatorfilter | Checkpressuresettingsevery2weeks |

Thesetpressureofbutterflyvalvemodel is0.25~0.35MPa |

| Condensatewaterfilter | Cleantheinnerfilteronceaweek |

Strengthenthedredgingofcoolingwater. Improverefrigerantcondensationeffect. Reducecompressorhighpressure. |

③ Refrigerated air dryer

| PartsName | MaintenanceContent | MaintenancePurpose |

| Watercooledcondenser | Cleanthecondenseratleast2timesayear |

Improvethecondensationeffectof compressedairdryersystem |

| Aircooledcondenser | Purgecondenseronceaweek |

Strengthenthecondensationeffect oftherefrigerant |

| Refrigerantcompressor | Checkoillevel,current,inlettemperature | —— |

| Bypassvalve | Adjusttheopeningaccordingtolowpressure | —— |

| Expansionvalve | Adjusttheopeningaccordingtolowpressure | —— |

| Dryfilter |

Replaceregularly.Replacedatthesametimeas thereplacementofrefrigerant |

—— |

| Refrigeranthighpressuregauge | Checkthepressurerangeoften | Normalvalue1.2~2.0MPa |

| Refrigerantlowpressuregauge | Checkthepressurerangeoften | Normalvalue0.35~0.45MPa |

④ desiccant air dryer for compressor

| PartsName | MaintenanceContent | MaintenancePurpose |

| Highqualitydesiccantbeads |

Generally,wereplacedesiccantbeads every2years.Butit’sbesttocheckthe adsorbentquarterly. |

Inordertoensurethewaterabsorption performanceoftheadsorbent |

| Pneumaticvalves |

Observethe4-valveactionsequence. Alsocheckthevalveforirrelevantproblems. |

Ensurethattheairintakeandexhaustarenormal. Atthesametimeeliminateairleakage. |

|

Mufflersilencerofcompressed airdryerdesiccant |

Observetheexhaust.Controltheairconsumption ofdesiccantairdryerforcompressor. |

WhentheABtowerduringregeneration,ifthepressure cannotbereduced,needtoreplaceit. |

| Diffuser |

Replaceregularly.Itisrecommendedtocheckthe diffuserwhenchangingthedesiccantbeads. |

—— |

7. Combinated compressed air dryer system troubleshooting (1) Poor water removal effect of refrigerant & desiccant air dryer for compressor

| Status | Reason | Troubleshooting |

| Pipingsystemerror | Bypassvalvenotfullyclosed | Closethedryerbypassvalve |

|

Airnotpassingthroughcompressedair dryerdesiccant&refrigeration |

Tightenthebypassvalve.Alsoopen theinlet&outletvalves |

|

| Dryernotlevel | putcompressedairdryersystemonlevel | |

| Autodraininclined | putitonlevel | |

| Toomuchairflow | Heatloadistoohigh | Re-designtheairsource |

| Abnormaldrainagesystem | Baddrain | Cleanorchangeit |

|

Abnormalevaporatoroutlet temperature |

Dewpointistoolowortoohigh | Adjustthepressureswitch |

| Ambienttemperatureistoohigh | Canstillusetheaircompressordryer | |

| Inlettemperatureistoohigh | Addarearcooler | |

| Refrigerantleakage,sopoorcoolingeffect | Repairleaks,thenaddrefrigerant | |

| Adsorbent not working well | Desiccant beads failure | Replace adsorbent for desiccant air dryer for compressor |

(2) Pressure drop too high

| Status | Reason | Troubleshooting |

|

Compressedairpiping systemerror |

Pipediameteristoosmall | Increasepipesize |

|

Thepipelineistoolongand therearetoomanyelbows |

Designpipingsystemagain | |

| Filterblockageinline | Replacefilterelement | |

| Toomuchairleaksatthepipeconnection | Checkelbowfittings | |

|

Thedryeraircapacityexceeds ratedvalue |

Exceedstheratedflowofcompressedair dryerdesiccant&refrigerant.Pressureis naturallyreduced. |

Replacingacompressedairdryer systemwithalargercapacity |

|

Condensedwaterinthe evaporatorfreezes |

Badtemperatureswitch | Renew,checkcircuit,correctswitch |

(3) Controller and adsorption system problems

| Status | Reason | Troubleshooting |

|

Programmablecontroller indicatordoesnotlightup |

Nocurrentinput | Checkvoltageonterminalblock |

| Thepowerswitchfails | Replacethepowerswitch | |

| Controllerinternalfault | Fixit | |

| Highoutletdewpoint | Aircapacityexceedsmaximum |

Changetocompressedairdryer desiccantwithbiggermodel |

| Thedesiccantpalletshaveexpired | Replacetheadsorbent | |

| Theadsorbentiscontaminated |

Firstly,checkthecompressedairfilters. Thenreplacethedesiccantbeads |

|

|

Intakepressuretooloworintakeair temperaturetoohigh |

Increaseintakepressureordecrease intaketemperature |

|

|

Itdoesn’treachtheworking pressurewhencharging |

Regenerationvalveisnotclosedtightly |

Overhaultheregenerationvalveof desiccantairdryerforcompressor |

| Toomuchdrycompressedair | Reducedrycompressedairoutput | |

|

Thepressureintheregeneration towerisgreaterthan0.02MPa |

Mufflerblocked | Cleanorreplace |

| Regenerationvalveisnotfullyopen | Fixtheregenerationvalve | |

| Poorcheckvalveseal |

Fixthecheckvalveofcompressed airdryersystem |

8. FAQ

CATEGORIES

LATEST NEWS

- Air compressor with oil-removal purifier for laser cutting machine

- How Does Refrigerated Compressed Air Dryer Work? Brief Guide

- Zero Air-loss HOC Heat of Compression Dryer Energy Consumption Analysis

- Six Air Compressor Calculation Formulas ~ Examples Demonstration

- What to Look for in Screw Compressor with Dryer | Expert Guide

CONTACT US

QQ: 89080830

Phone: +86-18080420046

Tel: +86-28-84369018

Email: 89080830

Add: Room 1010, Building 5,No.199,Road Huaishudianlu,City Chengdu,China