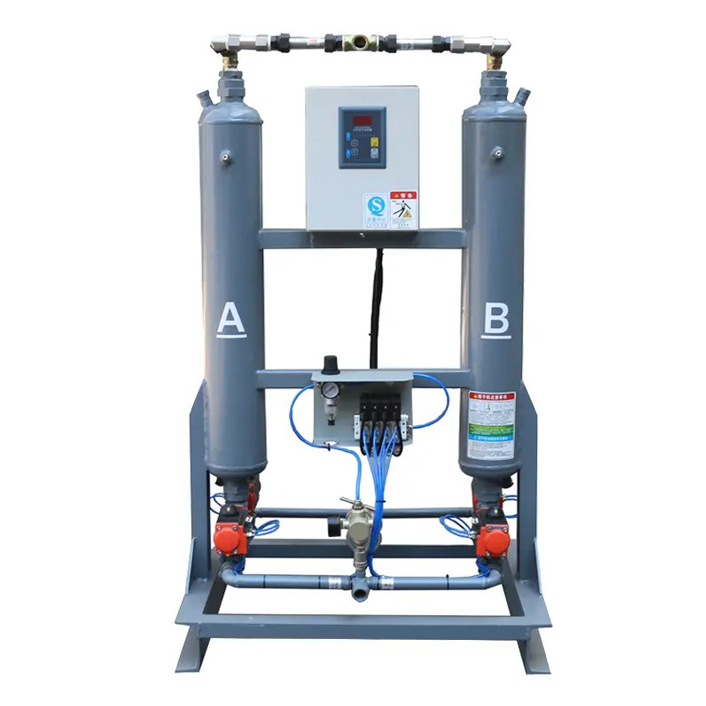

Desiccant Air Dryer

10.5m³/min Heated Adsorption Desiccant Type Air Dryer

- Product ID:Desiccant Air Dryer

- QQ:89080830

- Phone: +86-18080420046

- Tel: +86-28-84369018

- Email: topefg@hotmail.com

- Time: 2019-11-18 17:39:04

This is micro heat desiccant type air dryer. The dew point of heat regenerative adsorption dryer is -40℃. Of course, we can also customize -20℃ and -70℃ air dryer. Because we are factory, we can supply good price. Welcome to inquire our absorption type dryer.

1. What is heat regenerative adsorption air dryer?

It is twin tower desiccant type air dryer. It is not only a pressure swing adsorption dryer, but also a temperature swing adsorption dryer. Different from heatless air dryer, there is a heater. It adopts micro heating regeneration method. Then the absorb and dry the compressed air. Therefore, it reduces the regeneration air loss.

2. Technical sheet of heat regenerative air dryer

| Productname | microheateddesiccantairdryer |

| Inletairflow | Std.10.5Nm3/min|630Nm3/Hr|370CFM |

| Workingprinciple | PSApressureswingadsorption+TSAtemperatureswingadsorption |

| Dryerworkingperiod | 90~240min |

| Averageregenerationairloss | Std.6%|Min.3.5%Max.8% |

| Inletairpressure | Std.7bar|Min.6bar|Max.10bar |

| Airpressureloss | 0.2bar |

| Inletairoilrequirements | Oil-freecompressedairor≤0.1ppm(mg/m3) |

| Inletairtemperature | 10~30℃|Min.2℃Max.40℃ |

| Outletdewpoint | ≤-40℃OrLowerEnsure100% |

| Ambienttemperature | Min.2℃Max.45℃ |

| Adsorptionairdryerpower | 3.1KW |

| Heaterpower | 3.0KW |

| Heatingtemperature | UCL:180℃,LCL:170℃|smartthermostatcontrol |

| Absorptiontypedryerweight | 610Kg |

| desiccanttypeairdryersize | 1195×720×2175mm |

3. Why choose our heated desiccant type air dryer? (1) Low energy consumption

Compared to heatless air dryer, the air loss is much lower. The air loss of our heat desiccant type dryer is 6%. There add an independent electric heater. It improves the shortcomings of heatless regenerative dryer. That is, large regeneration air consumption, short switching cycle and high failure rate. The enegy saving rate can reach more than 40%. So it makes the operation costs lower.

In addition, it also uses thermostatic controller. Keep the regeneration air temperature constant. Then avoid the adsorbent from overheating.

(2) Our adsorption dryer has reliable dew point

Firstly, our adsorption air dryer adopts a long process design. So it can guarantee an extremely low dew point. Secondly, there are diffusers at the bottom of the adsorption tower. It ensures enough contact time between compressed air and adsorbent. If no this device, there would be “dead spots” for adsorption.

In addition, it can reduce the impact of air current on the desiccant beads. Thus, it guarantees the service life. Thirdly, our adsorbent filling is sufficient. So the dew point of our dryer is low and stable. Our dryer uses microcomputer intelligent automatic control. The air supply is continuous and stable. Intermittent air cuts will not occur. Easier to handle. Therefore, the dew point fluctuation is very small.

(3) High quality raw materials and spare parts

Our desiccant type air dryer uses two kinds of adsorbents. Namely high-efficiency activated alumina and molecular sieves. The desiccant has a long service life.

In addition, our dryer adopts wear-resistant pneumatic butterfly valve. Reliable performance and long life. Two-position five-way solenoid valve is also a well-known brand. So it ensure reliable operation of absorption type dryer.

(4) Strong customization ability

If need, we can add a SUTO dew point meter. In this way, it can achive TSE dew point energy saving control. Besides, a variety of control methods are available. That is, interlocking control, remote communication, and IoT control. They can adapt to different requirements.

In addition, we can customize lower dew points. It can reach -70℃. Moreover, we can also produce high pressure adsorption air dryer. Max pressure is up to 100bar.

(5) Work together with world famous air compressor brands

We are famous desiccant type air dryer brand in China. Moreover, our absorption type dryer usually work with famous compressor brands, such Atlas Copco, Ingersoll Rand, Kobelco, Hitachi, etc.

Heatless air dryer uses PSA principle. That is, pressure swing adsorption. But heated desiccant type air dryer is different. It uses the principle PSA + TSA. That is, pressure swing adsorption and temperature swing adsorption. Its specific workflow includes the following parts:

principle. That is, pressure swing adsorption. But heated desiccant type air dryer is different. It uses the principle PSA + TSA. That is, pressure swing adsorption and temperature swing adsorption. Its specific workflow includes the following parts:

(1) The adsorption drying process of desiccant dryer

Compressed air is passed through the drying A tower. Desiccant beads adsorb a large amount of water vapor. They are absorbed into the capillary pores and held. This will wait for the completion of drying B tower work. Then it starts cycle switching.

(2) Dryer regeneration process (i.e. desorption)

The regeneration process consists of the following steps:

① Pressure relief process

The regeneration tower must be depressurized first. Reduce to atmospheric pressure. Wait for the process to finish. Then enter the next process. We can hear the pressure release sound from the muffler.

② Heat purge process

The process utilizes a small portion of dry compressed air. The proportion accounts for about 3 to 8%. Firstly, expand the air through the throttle valve. Wait to near atmospheric pressure. Then enter the heater of adsorption air dryer. Start heating. Finally enter the adsorption tower. So it completes the heat purge.

Hot air flows down the pipe. Enter the wet absorbent from top to bottom. Remove and discharge the moisture. When the process ends, it will go to the next process.

③ Cold purge regeneration process

The heat purge process ends. At this time, the adsorbent is in a high temperature and dry state. So must cool to be ready for the next process.

Then the cooling process starts. The heater stops working. Still use 3-8% air as cold purge regeneration air. Also go through the throttle valve. Gradually reduce the temperature of the desiccant beads. After the process is over, it will go to the next process.

④ Pressure boost process

The cold purge process ends. Then regeneration exhaust valve is closed. Part of the air is gradually boosted through the throttle valve. And reach operating pressure. After this process is complete, it enters the standby state.

⑤ Standby process

The regeneration tower has been boosted. The adsorption desiccant type air dryer is waiting to switch.

⑥ TSE dew point energy saving control process

If there is a dew point meter, it can achieve this function. One of the towers completes regeneration. At this time, the “online tower” still maintains the adsorption state. TSE will detect its saturation in real time. If it is not saturated, it will prolong adsorption period. Therefore, it can guarantee a stable drying dew point. At the same time, it can save the energy consumption of regeneration. The whole process is fully intelligently controlled by PLC.

⑦ Process change

The desiccant beads in the adsorption tower is about to reach saturation. At this time, adsorption air dryer will automatically switch in advance. It’s to continue adsorption drying. This cycle works continuously.

5. Pressure swing adsorption dryer vs temperature swing adsorption dryer (1) Pressure swing adsorption

PSA has wide application in the drying of gases. Adsorb at higher pressure. Desorb under reduced pressure. This is called pressure swing adsorption.

Generally carry out desorption at atmospheric pressure. If simply adsorbs moisture under high pressure and reduce to atmospheric pressure, it has little desorption effect. After depressurization, must purge regeneration air with low relative humidity. In this way, the desorption can be completely desorbed. Then this is the PSA process of adsorption air dryer.

(2) Temperature swing adsorption

TSA refers to adsorption at lower temperature. Then desorb at higher temperature. This is another principle of desiccant type air dryer. Because the adsorption capacity will decrease with temperature increasing. During regeneration, the regeneration gas is purged to increase the temperature. So it will reduce the relative humidity.

FAQ

Q1: How long to change the desiccant beads in the adsorption air dryer?

A1: Generally, we need to replace the adsorbent about two years. Of course, it also depends on the use time of your dryer. In addition, different usage environments, different replacement cycles.

Q2: Do I need to install a refrigerated dryer in front of the desiccant type air dryer?

A2: In general, it is necessary to install a refrigerant air dryer. If there is a refrigeration dryer, the drying effect will definitely be better. Of course, it also depends on three points. That is, dew point, inlet air temperature and ambient temperature.

If the two temperatures are not high, and the dew point is -20°C or -40°C, then it is okay not to use a refrigerated dryer.For example, it is common not to install refrigerated dryers in Russia. But at this time, if the dew point is -70°C, then there must be a refrigerant dryer.

Q3: What spare parts do I need to purchase?

Aside from the adsorbent, the muffler is the most frequently replaced. So you can buy the silencer muffler together with the adsorption desiccant type air dryer.

CATEGORIES

LATEST NEWS

- Air compressor with oil-removal purifier for laser cutting machine

- How Does Refrigerated Compressed Air Dryer Work? Brief Guide

- Zero Air-loss HOC Heat of Compression Dryer Energy Consumption Analysis

- Six Air Compressor Calculation Formulas ~ Examples Demonstration

- What to Look for in Screw Compressor with Dryer | Expert Guide

CONTACT US

QQ: 89080830

Phone: +86-18080420046

Tel: +86-28-84369018

Email: 89080830

Add: Room 1010, Building 5,No.199,Road Huaishudianlu,City Chengdu,China