Desiccant Air Dryer

HRB-E Series Blower Heated Micro Gas Consumption Regenerative Adsorption Desiccant Dryer

- Product ID:Desiccant Air Dryer

- QQ:89080830

- Phone: +86-18080420046

- Tel: +86-28-84369018

- Email: topefg@hotmail.com

- Time: 2019-11-25 23:05:01

Features of Air Compressor Desiccant Dryer

A. Ultimate energy saving

Compared with the fixed cycle mode, the self-developed ebz200-2 multi-core drive can save more than 10% of the comprehensive energy consumption; the dew point energy-saving control can be selected, and the adsorption time of a single tower can be prolonged under the condition of load fluctuation, and the comprehensive energy consumption can be reduced by more than 30%. Compared with the traditional heatless regenerative dryer, it can save more than 70% energy and is the best choice for matching centrifuge and oil-free screw compressor.

|  |  |

B. High-end product configuration

*High-performance pneumatic valve, reliable performance, long service life;

*Taiwan brand high-pressure fan;

*International brands such as French Schneider are selected for electrical components;

*Siemens PLC controller, Kunlun Tongtai 7 inch large screen touch screen, dynamic monitoring of the operation process;

*Customized high-performance adsorbent, designed filling allowance of 20%;

*304 stainless steel control air source pipeline, beautiful and elegant;

*The specially designed diverter has high adsorbent utilization and low gas pressure loss;

* High-efficiency cooler was designed by HTFs software;

|  |

C. Precise control system

*Through RS485 communication interface MODBUS-RTU communication protocol (if other communication protocols are adopted, it will be determined by negotiation separately), collect equipment operation parameters, remote start and stop control, upload and realize the monitoring of operation status and various fault information;

*The most comprehensive signal acquisition, monitoring and display, including inlet temperature, heater temperature, regeneration tail gas temperature, a / b tower pressure, fan pressure, dew point temperature (optional)

Working Principle ofAir Compressor Desiccant Dryer

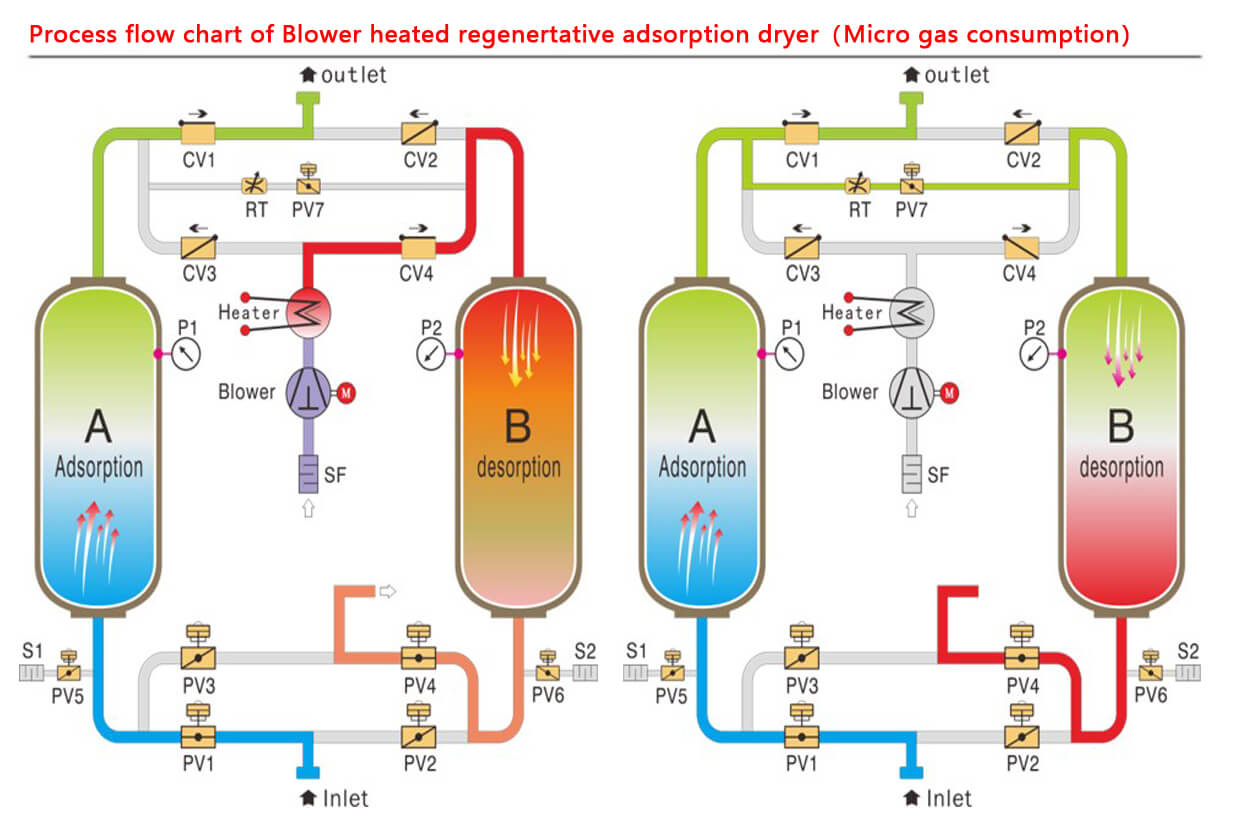

The blower heated regenerative adsorption desiccant dryer(Micro gas consumption)is composed of two adsorption towers that work alternately, including blower, electric heater system, switching valve system, control system, etc. In the whole working cycle, one adsorption tower is in adsorption, the other adsorption tower is in regeneration desorption. On the basis of the micro heat regeneration adsorption dryer, an independent high-efficiency blower is added. The ambient air inhaled by the blower is heated by the heater to desorb the moisture from the adsorbent. In the cooling stage, about 2% of the finished gas is used as the regeneration gas. The whole regeneration process consumes very little compressed air.

Advantages of Air Compressor Desiccant Dryer

A. Strong manufacturing capacity

Professional compressed air post-processing manufacturer with 11 years of independent production experience.

The core components (evaporator, radiator, heat exchanger, sheet metal, water separator, etc.) are all produced independently with controllable quality.

Own sophisticated automated production equipment.

More than 130 production workers with rich experience and responsibility.

With an annual output of more than 20thousand dryers and filters, serving more than 70 thousand customers worldwide.

B. Senior design team

The design team is composed of more than 10 senior technical engineers, with rich industry experience and customization capabilities.

With an independent laboratory.

CATEGORIES

LATEST NEWS

- Air compressor with oil-removal purifier for laser cutting machine

- How Does Refrigerated Compressed Air Dryer Work? Brief Guide

- Zero Air-loss HOC Heat of Compression Dryer Energy Consumption Analysis

- Six Air Compressor Calculation Formulas ~ Examples Demonstration

- What to Look for in Screw Compressor with Dryer | Expert Guide

CONTACT US

QQ: 89080830

Phone: +86-18080420046

Tel: +86-28-84369018

Email: 89080830

Add: Room 1010, Building 5,No.199,Road Huaishudianlu,City Chengdu,China