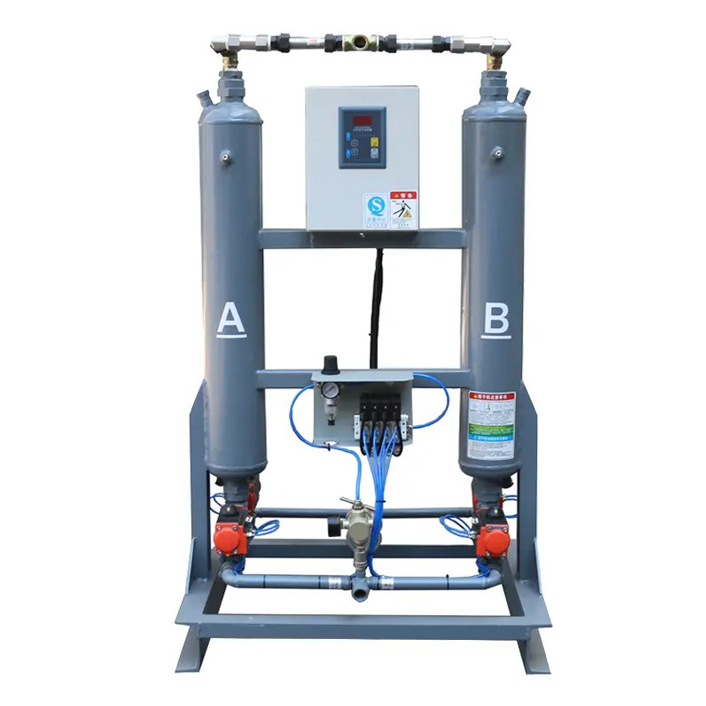

Desiccant Air Dryer

210m³/min Zero Air Loss HOC Type Absorption Air Dryer

- Product ID:Desiccant Air Dryer

- QQ:89080830

- Phone: +86-18080420046

- Tel: +86-28-84369018

- Email: topefg@hotmail.com

- Time: 2019-11-18 13:05:37

Our company is high quality absorption air dryer manufacturer in China. This HOC dryer is energy-saving. Because it is zero air consumption heat of compression dryer. Compared with heatless regenerative dryer, it can save energy by about 80%. Additionally, it is 70% more energy efficient than micro heat adsorption dryer.

This absorption dryer mainly includes three parts. That is, drying, cooling and heating system. Oil-free air compressor discharges hot air. The HOC dryer makes full use of these heat. Then heat the adsorbent desiccant for regeneration. On the one hand, there is no air consumption during regeneration process. On the other hand, it cancels the electric heater of the micro-heat desiccant dryer.

Technical sheet of zero air loss HOC dryer

| Equipmentname | zeroairconsumptionheatofcompressiondesiccantdryer |

| Inletaircapacity | Std.210.0Nm3/min|12600Nm3/Hr |

| Dryerworkingprinciple | TSAtemperatureswingadsorption+splitflowcycleregeneration |

| Workingperiod(singletower) | ≈240min|Max.300min |

| Regenerationairloss | 0% |

| Inletairpressure | Std.7bar|Min.6barMax.10bar |

| Pressurelossatfullload | ≤7%ofinletpressure |

| Inletairoilrequirements | Oil-freecompressedair |

| Inletairtemperature | Std.140℃|Min.120℃,Max.180℃ |

| Outletpressuredewpoint | ≤-40℃ |

| Absorptionairdryerpower | 50.2KW |

| Blowerpower | 7.5KW |

| Electricheaterpower | 50KW(heatingby40%flow) |

| Heatingtemperature | UCL:150℃,LCL:120℃ |

| Coolingwaterflow | ≤116T/Hr |

| Coolingwaterpressure | Std.3barMin2barMax:6bar |

| Coolingwatertemperature|temperaturerise | Std.20℃Min2℃Max:27℃|5℃ |

| Absorptiondryerweight | 12000Kg |

| HOCairdryersize | 2950H×5000L×3200W |

Why choose our zero air loss HOC type absorption air dryer? (1) This adsorption dryer is most energy efficient

Among all the adsorption air dryers, this one is the most energy efficient. Compared to normal HOC dryer, it adds auxiliary high efficiency cooler. So it achieves complete zero air consumption. Compared with heatless air dryer, it can save energy by about 80%.

Now let’s take an example. And compare the energy consumption of different desiccant dryers. For instance, there is a 175m³/min oilless centrifugal air compressor. And the power is 925KW. Assume that the centrifugal air compressor works 365 days a year. At the same time, it runs continuously each day. In addition, the electricity fee is CNY1.05/kWh. And water fee is CNY0.22/ton.

Specific energy consumption of each absorption dryer:

| No. | AirCompressorAirDryer | Calculationofenergyconsumption foreachabsorptionairdryer | Annualoperationfees | Comparedtoheatlessdryer, howmuchenergyitcansave? |

| 1 | Heatlessdesiccantairdryer | Theratioofregenerationair consumptionisabout15%. (925KW×15%)×24h×365d×CNY1.05 =CNY1276222/year | CNY1276222 | Highenergyconsumption |

| 2 | Heatregenerativeadsorptiondryer | Singletowercycleis4h.Additionally, regenerationairvolumeis8%.And heaterpower70KW.Heatingtime1.5h. Coldpurgetime2.0h. (925KW×8%×3.5h+70KW×1.5h×75%)× 6times×365d×CNY1.05=CNY776656/year. | CNY776656 | 39.10% |

| 3 | Zeroairlossblowerpurge desiccantdryersystem | Absorptioncycleis4h.Zerogasconsumption. Heatingtime1.5h.Heatingpower110KW. Inaddition,coldpurgetime2.0h.Blowerpower 18KW.Andblowerstarttimeis3.5h. (110KW×1.5h×75%+18KW×3.5h)×6times×365d× CNY1.05=CNY429431/year | CNY429431 | 66.30% |

| 4 | MicroairconsumptionHOCdryer | Theadsorptioncycleis4h.And5%ofcoldpurge airconsumption.Coldpurgetime1.5h.Coolingwater consumption:90t/h. Powerconsumption:(925KW×5%×1.5h)×6times× 365d×CNY1.05=CNY159527/year; Waterconsumption:90t/h×24h×365days×CNY0.22 =CNY173448/year; Sothetotalenergyconsumptionofthisabsorption dryer=CNY159527/year+CNY173448/year=CNY332975/year | CNY332975 | 73.90% |

| 5 | ZeroairlossHOCdryer | Theadsorptionperiodofabsorptionairdryeris4h. Coolingwaterconsumption:135t/h. Waterconsumption:135t/h×24h×365days×CNY0.22 =CNY260172/year | CNY260172 | 79.60% |

(2) The dew point of our desiccant air dryer is very stable

Our HOC dryer is with EBZ200-2 multi-core drive intelligent control system. Besides, it adopts PLC for intelligent control. It automatically adjusts for optimum operating efficiency. And it ensures the thorough regeneration. Therefore, the dew point is much more stable.

In addition, there are air distribution devices at the bottom of the dryer. This increases the contact time with the adsorbent. Make sure the dew point temperature meets the requirements. Our zero air loss absorption dryer can reach -20 and -40℃.

(3) Use high performance metal seated pneumatic butterfly valve

The temperature conditions of HOC dryer vary greatly. Ordinary valve gaskets are prone to aging and deformation. So it will cause the valve to not seal tightly. Finally it will affect the performance of absorption air dryer. In particular, it affects the dew point of desiccant dryer.

In order to eliminate these problems, we use high-performance metal seat valves. They can withstand high temperatures. Besides, it is a German original brand.

(4) Our absorption dryer is with high quality and sufficient amount of desiccant beads

Firstly, our HOC dryer has ample desiccant beads. 25~28kg adsorbent per cubic air. Therefore, it can maintain a high drying effect.

Secondly, choose a well-known brand of adsorption desiccant. The particle size is 3~5mm. Good water resistance. Moreover, we use the best filling method. It can prevent desiccant from sinking. So it has longer service life.

How does zero air consumption absorption air dryer work?

Our refrigerative air dryer uses AL2O3. And AL2O3 has a very obvious feature. That is, its adsorption capacity is strong at high pressure and low temperature. And it is weak at high temperature and low pressure.

Apply AL2O3 to a HOC dryer. The maximum temperature is 110°C. Due to the increasing temperature, its water absorption capacity is reduced. Therefore, AL2O3 will release a lot of water into the air. It achieves the effect of regeneration. This is in line with the TSA working principle.

The working principle of zero air loss HOC absorption dryer is as follows: the centrifugal air compressor exhaust high temperature air. And it will take advantage of these heat. It take direct heating for the adsorbent. Completely remove moisture to achieve regeneration. There is no air consumption during heating process. So it saves energy as much as possible.

Specific workflow of “heat of compression” dryer

(1) The adsorption drying process of HOC dryer

In fact, this process is same to other absorption air dryers. Adsorbents hold water vapor. This process continues until another tower finishes regeneration process.

(2) Regeneration process of desiccant air dryer, i.e. desorption

The regeneration process consists of 3 steps: that is, twin towers co-current → {hot purge → thermal delay → cold purge} → twin towers co-current

① Two towers co-current

Sometimes absorption air dryer shuts down abnormally. So this can avoid affecting the outlet temperature.

② Thermal purge process

Take tower A adsorption as an example. The high temperature air enters the B tower from the V2 valve. Then it start thermal purge from top to bottom. Afterwards, they will be cooled to the adsorption temperature by the main cooler. Finally enter Tower A.

③ Cold purge process

The thermal purge process ends. At this time, desiccant beads are in a dry state. So it must cool to be ready for the next adsorption. Then the cold purge process starts.

The high temperature air is cooled to about 40℃ by the main cooler. Then it perform cold purge to tower B through the V4 valve. Next, flow through the auxiliary cooler to cool to the adsorption temperature. Finally, enter the A tower from V8 and V5.

FAQ Q1: For HOC dryer, it can achieve the dew point that -40℃?

A1: In fact, the use of compression heat dryers is conditional.

It is generally only suitable for centrifuges and oil-free screws. Compressed air inlet temperature should be above 110°C. Besides, the dew point requirements are not strict. For example -20℃, or -40℃. At this time, the energy saving of HOC absorption dryer is beyond doubt. It can achieve zero air consumption.

But sometimes customer requirements are very strict. For example, they require dew point lower than -40℃. And the inlet temperature is not guaranteed to always reach 110°C. Then the energy saving of HOC absorption air dryer will be greatly reduced. At this time, we should choose micro air consumption dryer. It’s bettern than zero air loss HOC adsorption dryer.

Q2: Does the HOC dryer have strict requirements on the inlet air temperature?

A2: Yes. For HOC absorption air dryer, we must confirm the inlet air temperature. It usually cannot be lower than 110°C. Sometimes the intake air temperature is lower than 110°C. Besides, users have strict requirements on dew point. Then the desiccant dryer must add auxiliary heating.

Q3: What’s the cycle time of your zero air loss HOC absorption air dryer?

A3: For single tower, it’s about 240 minutes. Namely 4 hours. Many people believe that long-term operation is good. And think it shows the energy saving and performance of adsorption dryer. But this does not apply to zero air-loss desiccant air dryer.

For other dryers, regeneration process releases moisture-laden air into the atmosphere. But HOC absorption dryer is different. It will carry some of the moisture from the previous cycle to the next cycle. The cycle adsorption capacity of HOC dryer is much larger than other dryers. Therefore, if need same dew point, we can increase filling amount of the adsorbent. But shortening the adsorption cycle is the best way. So short cycle time is good for zero air loss absorption air dryer.

CATEGORIES

LATEST NEWS

- Air compressor with oil-removal purifier for laser cutting machine

- How Does Refrigerated Compressed Air Dryer Work? Brief Guide

- Zero Air-loss HOC Heat of Compression Dryer Energy Consumption Analysis

- Six Air Compressor Calculation Formulas ~ Examples Demonstration

- What to Look for in Screw Compressor with Dryer | Expert Guide

CONTACT US

QQ: 89080830

Phone: +86-18080420046

Tel: +86-28-84369018

Email: 89080830

Add: Room 1010, Building 5,No.199,Road Huaishudianlu,City Chengdu,China